Torsion Spring

Product Introduction

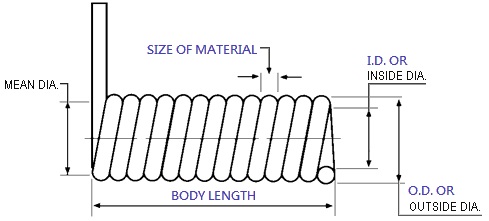

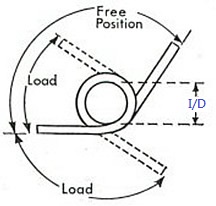

With the effect of bending stress, the Torque Spring is mainly used for storing and releasing energy. Its orientation (clockwise and counter clockwise), angle, length and terminal pattern of the spring is designed according to different working environments. We provide production services and the winding of springs for various applications ranging from small electronic equipment parts and motorcycle starting springs to 10mm double-torque spring of office chairs. The entire process is controlled by CNC Spring Molding Machine for manufacturing torque springs with a wire diameter up to 12.0mm while providing high-stability bending quality.

Specifications or drawing are welcomed and we will discuss further details with you.